| Availability: | |

|---|---|

| Quantity: | |

QT4-15

yixin

8474809090

20 kw

7600

6.2ton

2.Product advantages brick making machine in india |

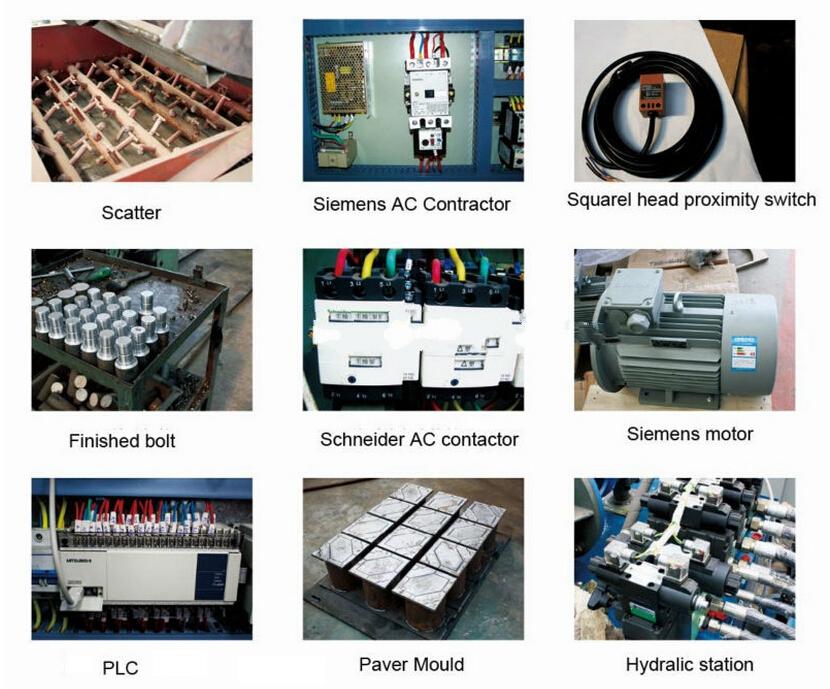

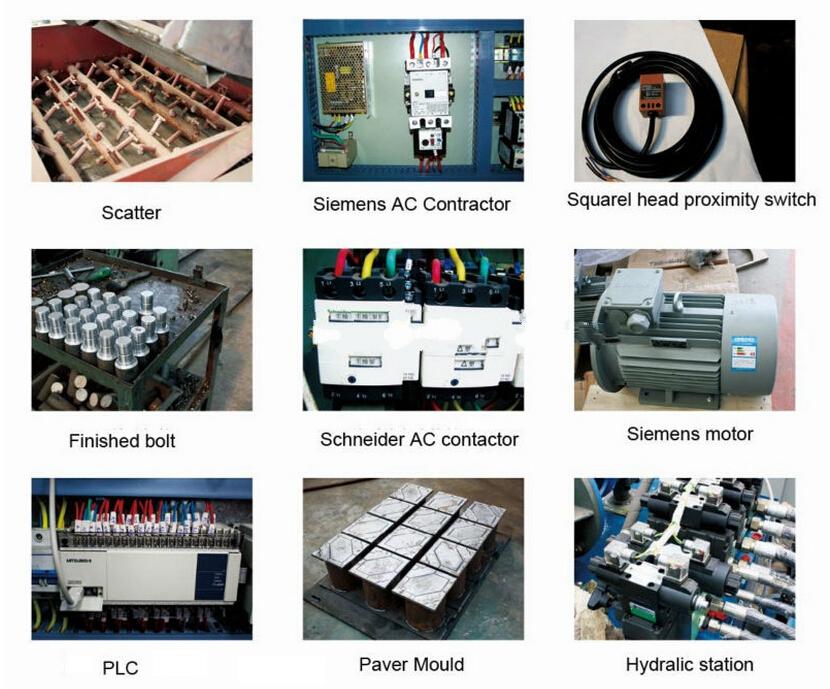

1.Frequency Conversional Control Technology:This automatic block making machine makes use of the frequency conversion control to keep the accurate and parrallel movement between tamper head and mould |

2.Double High Dynamic Directional Valves:Regulating the oil flow and pressure automatically,this valves is applied to protect the hydraulic cylinder from damage because of inertia |

3.The valves are able to facilitate the production stability effectively |

4.Multi-shaft Rotating at 360 and Compulsory feeding:this uniform feeding is suitable for various raw material and moulds |

5.Our automatic block making machine offers the feeding device with fast rotation,the raw material is mixed evenly to ensure the density and intensity of the blocks. |

6.German Siemens PLC Control System,Touch Sreen and Electrical Components |

7.Thermal Treatment on Moulds and Main Parts of the Machine |

Feeding System

Motor use reduce motors, which control two mixing shafts. Feeding frame, bottom plate and mixing blade are

made of high-duty steel , the location of bottom plate can be adjusted.Feeding system have sealing device

to prevent leakage. The door of the discharging gate is controlled by the reduce motor.

Germany Siemens PLC control system, Siemens touchscreen, Germany

Easy operation,low failure ratio, machine running stability and high reliability.Use the most-advanced industrial

internet technology, realize remote trouble-shooting & maintenance. PLC and touchscreen use the PROFINET

internet together, convenient for system diagnosis and WEB expansion. Achieve problem diagnosis and alarm

system constantly, convenient for machine maintenance and troubleshooting. PLC running data for permanent

preservation.

Land requeire: 20meter length, 10 meter width, 8 meter highet if silo request.

storeage yard at least 1500 ㎡.

2.Product advantages brick making machine in india |

1.Frequency Conversional Control Technology:This automatic block making machine makes use of the frequency conversion control to keep the accurate and parrallel movement between tamper head and mould |

2.Double High Dynamic Directional Valves:Regulating the oil flow and pressure automatically,this valves is applied to protect the hydraulic cylinder from damage because of inertia |

3.The valves are able to facilitate the production stability effectively |

4.Multi-shaft Rotating at 360 and Compulsory feeding:this uniform feeding is suitable for various raw material and moulds |

5.Our automatic block making machine offers the feeding device with fast rotation,the raw material is mixed evenly to ensure the density and intensity of the blocks. |

6.German Siemens PLC Control System,Touch Sreen and Electrical Components |

7.Thermal Treatment on Moulds and Main Parts of the Machine |

Feeding System

Motor use reduce motors, which control two mixing shafts. Feeding frame, bottom plate and mixing blade are

made of high-duty steel , the location of bottom plate can be adjusted.Feeding system have sealing device

to prevent leakage. The door of the discharging gate is controlled by the reduce motor.

Germany Siemens PLC control system, Siemens touchscreen, Germany

Easy operation,low failure ratio, machine running stability and high reliability.Use the most-advanced industrial

internet technology, realize remote trouble-shooting & maintenance. PLC and touchscreen use the PROFINET

internet together, convenient for system diagnosis and WEB expansion. Achieve problem diagnosis and alarm

system constantly, convenient for machine maintenance and troubleshooting. PLC running data for permanent

preservation.

Land requeire: 20meter length, 10 meter width, 8 meter highet if silo request.

storeage yard at least 1500 ㎡.

machine capacity:

type | specification mm | pcs/pallet | pcs/hour | pcs/8 hours |

hollow block | 400*200*200 | 4 | 720 | 5760 |

solid brick | 240*115*53 | 26 | 6240 | 37400 |

paver | 200*100*60 | 16 | 2880 | 23040 |

machine capacity:

type | specification mm | pcs/pallet | pcs/hour | pcs/8 hours |

hollow block | 400*200*200 | 4 | 720 | 5760 |

solid brick | 240*115*53 | 26 | 6240 | 37400 |

paver | 200*100*60 | 16 | 2880 | 23040 |

INDIA |  INDIA |  ZAMBIA |

INDIA |  INDIA |  ZAMBIA |

KERBSTONE |  SOLID BRICK |  RIPPLE PAVER |

KERBSTONE |  SOLID BRICK |  RIPPLE PAVER |

NO.69 JINHE ROAD,XIAMEI TOWN,NAN'AN CITY ,QUANZHOU CITY ,FUJIAN PROVINCE

+86-595-22963811

+86-595-22963811